The Building Envelope

The building envelope represents the single greatest impact on a home's space heating (and cooling) needs. The Montana state Department of Environmental Quality estimates that 49% of a household's annual energy use is dedicated to space heating. It is well known that conservation is the first step to energy reduction, and the ability of the building envelope to conserve energy by insulating and sealing the living space is critical.

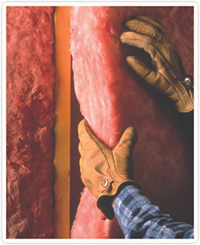

Insulation:

Insulation value, generally expressed as R-value, measures the envelope's ability to keep heat from moving through the envelope assembly. Current energy codes require insulation values of R-21 in walls and R-49 in roofs, so the first step is to increase insulation. The most common insulation material is fiberglass in walls and cellulose in ceilings, which have limited potential due to the amount of depth required to achieve higher R-values. Rigid Styrofoam boards and sprayed urethane insulation have much higher R-values per inch, and can significantly increase insulation performance in the same amount of space, but generally incur increased costs.

Thermal Bridging:

But the R-value applies only to the insulating material itself. Thermal bridging can reduce a traditional stud wall's true R-value as a system by 15% to 25% from its insulation R-value. Thermal bridging is the consequence of having a thermally unbroken member span from one side of the wall plane to another. The most common thermal bridge is a wood stud, which spans from interior wall board to exterior sheathing. Headers, windows and doors, blocking, even floor joists can all create thermal bridges.

Air Infiltration:

Air infiltration abatement deals with minimizing the amount of conditioned air lost to the outside, and unconditioned outside air infiltrating the building envelope. Air leakage can account for 20% to 40% of the energy used to heat and cool a home. Attention to detail is critical for window and door installation to correctly deal with potential air and moisture infiltration at wall penetrations. Vents, wall switches, electrical outlets and roof/ wall connections are other places where air infiltration can occur.

Heat Gain:

Though not as critical in the Montana climate, heat gain in the building during summer months should also be considered. Window placement and glazing in windows and doors should be fine tuned to the building's orientation to account for heat gain. West facing windows in particular are most susceptible to heat gain, as the hottest part of the day brings the sun almost parallel to west facing walls.

Conclusions:

Increasing insulation and minimizing thermal bridging and air infiltration can dramatically increase the performance of the building envelope. Not only does this reduce energy costs, but can also results in an immediate cost savings in down sizing of mechanical equipment. These can also have implications on occupant comfort, by mitigating drafts and temperature swings in the space.

Taking all this into consideration, it was decided that a Structurally Insulated Panel (SIP) wall construction was the most cost effective way to increase the insulation, reduce thermal bridging and reduce air infiltration. SIP construction has also been successfully used throughout the state, and has an excellent performance track record. In the roof assembly, a combination of spray urethane and blown loose-fill insulation was used with a conventional truss roof. The urethane, 5" at the truss heels and flashed (appx 1") to the backside of the ceiling gyp board, provided an excellent air seal and insulated tough spots like the truss heels. The loose-fill made up the rest of the insulating value at the best price. Urethane insulation was also used at the rims of the floor joists to a depth of 4", and at all door and window frames to seal the penetrations.

The window package consists of good quality aluminum clad wood windows. The glazing is a thermal pane (2 layers of glass with an air space) unit with a LowE 366 coating. The LowE coating provides better insulating value, reduced solar heat gain, and excellent UV control. The U-value of the operable windows is .35, the minimum allowed by Energy Star. Two other "high performance" window packages were investigated, but because the wall and roof construction had already been optimized, their impact was not great enough to merit the increased cost. It was estimated, based on decreased heating demand during winter months, that the payback period would be close to 40 years. While each project design should be evaluated for its climate and orientation, in this case the benefit just wasn't there.